Nature of Fashion: Design for Transformation

Rethinking Textile Waste by Learning from Nature’s Strategies.

The international research initiative is rethinking textile value creation – beyond linear systems. Project teams in the global North and South are researching how critical textile waste can be converted into valuable, biocompatible materials with the help of biotechnological solutions and integrated into new, safe material cycles. The initiative was launched by the Biomimicry Institute and funded by the Laudes Foundation. In Berlin-Brandenburg, the Beneficial Design Institute, together with Fraunhofer Institute and other partners, and funded by the Brandenburg Ministry of Climate Protection and the Federal Ministry of Economics, is developing processes that transform mixed waste textiles into new recyclable materials for medicine, agriculture and packaging. The initiative combines design research, biotechnology and system innovation from feasibility studies to a scalable model of regional circular economy – with the aim of enabling regional value creation from textile waste and actively promoting the design of a nature-based, regenerative fashion and textile industry.

The fashion and textile industry system exists within Earth’s planetary boundaries and hence must operate within the ecological limits of our planet. Recognizing that the current "take-make-waste" model has already exceeded Earth’s planetary boundaries, the Nature of Fashion: Design for Transformation initiative calls for a radical redesign of how we handle textile waste by learning from nature’s most fundamental strategy: transformation through breakdown and renewal.

Global Initiative

The aim of the international research initiative is to fundamentally redesign the way we deal with textile waste and to model it on natural regeneration processes. Instead of following the linear principles of "take, make, waste", the project focuses on a cyclical understanding of material use. At its core is a "break down to build up" approach that combines biological and biotechnological processes to transform mixed textile waste into biocompatible raw materials that can be returned to safe cycles. These materials are intended to be industrially applicable in areas such as medicine, agriculture and packaging, while contributing to the development of a nature-positive, regenerative economy.

Regional Pilot Projects

Partner organisations – including the Beneficial Design Institute in Germany, Circle Economy in the Netherlands and The Or Foundation in Accra, Ghana – are developing and testing Design for Transformation with various regionally anchored strategies and approaches, each contributing to a broader spectrum of regenerative toolkits.

The initiative is now in its second phase, building on the success of the first pilot projects, which demonstrated both the technical feasibility and complexity of converting mixed textile waste into reusable and increasingly non-toxic materials.

Initiator

Biomimicry Institute

Global Partners

Circle economy, Or Foundation, Beneficial Design Institute

Services Beneficial Design Institute

Strategische Projektentwicklung und Netzwerkaufbau in der Region, Design Forschung & Entwicklung, Textilabfallanalyse, Markt- und Potenzialanalyse, Produktapplikation

Team

Friederike von Wedel-Parlow, Isabella Rhein, Leoni Otto, Julie Stamm, Iris Blackwood, Esther Werring, Noemi Kelleova

Regional Partners

Fraunhofer IAP, Fraunhofer IGB, matterr GmbH

Publications

Please fill in your email address to download the document.

Share

Pilot Region Berlin-Brandenburg, Germany

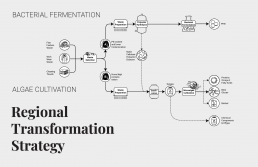

As an implementation partner in the Berlin-Brandenburg metropolitan region, the Beneficial Design Institute is researching new forms of regional circular infrastructure in collaboration with Fraunhofer IAP, matterr GmbH and Fraunhofer IGB. The focus is on developing biotechnological processes, including the collaboration with bacteria and microalgae, to divert low-value post-consumer textile waste from its current path to incineration and convert it into high-quality, biocompatible materials.

Our work will now be expanded to include scaling and synchronising the processes and improving system efficiency. We will also test the economic viability of these biocompatible products, optimize their conversion processes and evaluate the economic and ecological impact of expanding these efforts in more detail.

Feasibility and Potential for the Region

In the proof-of-concept phase, we are working with the two project consortia to develop and test complementary processes for different waste classes and investigate their feasibility: on the one hand, the conversion of textile waste containing polyester in particular into the biopolymer polyhydroxybutyrate (PHB) through polyester hydrolysis and bacterial fermentation, and on the other hand, the utilisation of synthesis gas from the remaining textile waste with the help of microalgae cultivation into beta-glucan. Both approaches demonstrate how waste streams can be systematically converted into new recyclable materials.

Transformation through Bacterial Fermentation

How can polyester-containing textile waste from fast fashion, workwear and industrial cleaning rags be recycled efficiently and innovatively? To this end, we developed a biologically integrated circular system in collaboration with Fraunhofer IAP in Potsdam and matterr GmbH as part of the feasibility and potential study "Applications for the biopolymer polyhydroxybutyrate (PHB) from textile waste" funded by the Brandenburg Ministry of Climate Protection. This study is pioneering in nature. It has been successfully demonstrated that the lowest category of textile waste, previously considered worthless, can be converted into PHB, a thermoplastically processable and biodegradable bioplastic, by means of bacterial fermentation. In addition, the study showed how this waste can be used as a resource and raw material for a wide range of applications and product portfolios in a marketable way.

Fraunhofer IAP

The Fraunhofer Institute for Applied Polymer Research (IAP) specializes in the development and application of innovative polymer materials. It supports companies and partners in researching and optimizing sustainable materials and processes. The institute focuses on the production and processing of environmentally friendly, economically viable polymers at laboratory and pilot scale. Fraunhofer IAP has been exploring biopolymers derived from textile waste and is working toward a joint consortium for the utilization of cellulose from polycotton waste.

matterr GmbH

matterr GmbH (formerly RITTEC 8.0 Umwelttechnik GmbH) specialises in advanced polyester recycling using its innovative depolymerisation technology, which enables the efficient transformation of mixed, complex PET-rich waste streams – including mixed polyester textiles – into high-quality raw materials. As part of the pilot project, matterr GmbH is contributing its state-of-the-art process expertise to support the conversion of polyester-rich textile waste into valuable monomers for new, biocompatible materials.

Transformation through Micro Algae Cultivation

At the same time, we are working with Fraunhofer IGB as part of the IGP funding programme of the Federal Ministry of Economics to focus specifically on the cultivation of microalgae as a sustainable technology, with a particular emphasis on the production of beta-glucan. Specifically, the CO2-rich exhaust gas stream after the planned syngas fermentation is to be used to cultivate microalgae. The aim is to define the required quality of the CO2-rich gas stream after syngas fermentation for the planned application and to explore potential product applications and markets.

Fraunhofer IGB

The Fraunhofer Institute for Interfacial Engineering and Biotechnology (IGB) develops interdisciplinary solutions in biotechnology and process engineering. Its portfolio includes microorganism and algae cultivation, process optimization, and resource-efficient bio-manufacturing. Within the pilot project, Fraunhofer IGB uses syngas from textile gasification for the cultivation of beta-glucan via microalgae systems, opening new possibilities for agricultural and bio-based applications.

Textile Waste Analysis for the Region

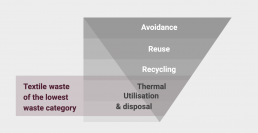

The initiative aims to recycle the lowest category of waste, previously considered worthless, as an important supplement to higher-value recycling methods such as rewear, reuse and recycling. The intention is to prevent textile waste from being disposed of through incineration or landfill in the Global South.

As part of the project, we examined three different textile waste streams in the lowest waste category. Industry partners provided significant support for the feasibility and potential analysis with their expertise and the necessary used and sorted test materials:

MEWA Textil-Service SE & Co. Management OHG , a textile service company offering a full service for workwear and cleaning cloths on the European market.

Sitex – Textile Dienstleistungen Simeonsbetriebe GmbH , a textile service company specialising in workwear and service textiles for use in medical facilities.

IZ Circular Textiles GmbH / SOEX focuses on the Europe-wide collection and sorting of used textiles and the global marketing of second-hand goods and secondary raw materials.

Textilhafen is part of Komm & Sieh gGmbH, a non-profit inclusion company run by the Berliner Stadtmission with a focus on clothing banks for homeless people and regional textile cycles in neighbourhood shops and the Textilhafen.